Gunnar Kleveland, center, president and CEO of Albany International cuts the ceremonial ribbon for the official opening of the company’s new world headquarters at the Pease International Tradeport in Portsmouth, Joining Kleveland were, from left, Nate Hastings, vice president, Chamber Collaborative of Greater Portsmouth; Suzanne Purdum, chief human resources officer, Albany International; Gov. Kelly Ayotte; Rob Hanson, chief technology officer, Albany International; Elizabeth Chilton, president of the University of New Hampshire; Kleveland; Joseph Gaug, general counsel, Albany International; Brian Tullis, chief information officer, Albany International; Will Station, chief financial officer, Albany International; and Ben VanCamp, president, Chamber Collaborative of Greater Portsmouth. (Courtesy)

When Gunnar Kleveland took the reins as president and CEO of Albany International Corp. two years ago, its offices were spread among Rochester in New Hampshire, Albany, N.Y., and elsewhere.

“So it became important to me and to the leadership team: As we grow, we need to be together and we need to find a place to be together,” said Kleveland.

After what he described as “a full search for where that headquarters was going to be,” the company settled on 325 Corporate Drive at the Pease International Tradeport in Portsmouth, the former home of Bottomline Technologies. It celebrated the opening of its new home with a ribbon cutting Oct. 16.

Albany International develops and manufactures components using advanced materials for the paper and aerospace industries. Its two main businesses are Machine Clothing, which produces custom belts for paper production, and Albany Engineered Composites, which supplies advanced composite parts for the aerospace industry.

In talking about Albany International during his remarks at the ribbon cutting event, Kleveland summarized the company’s work this way: “We are good weavers.”

“We are a global leader in advanced material science. We’re really good at weaving. And what’s interesting is that we weave for the paper industry and we weave for the aerospace Industry,” he said. “Those are two wildly different businesses to be in and sometimes it’s really hard to explain to people why we do it. But we are good weavers and we take that technology and we bring it out to solve problems for our customers.”

He cited two examples of their work.

“And when you see things like paper, our product is the only product that touches the paper,” he said about the engineered belts used in the production process.

“When you walk onto a 737 Max or a A320 Neo and you look to the right as you’re walking onto the airplane, you see the big engine. On the front of that engine, there is a fan blade. That’s what we make,” he added.

For the latter, Albany International has had a long-standing manufacturing arrangement with Safran, a French aerospace company that makes the fan blades at the Albany Safran Composites production facility in Rochester’s Granite State Business Park.

According to Kleveland, its Rochester office, located on Airport Drive near the production plant will continue to do research and development work, and hiring will continue there.

Kleveland said the company’s next phase is developing products in the realm of hypersonics, the scientific discipline of looking at the effects of moving at speeds greater than Mach 5 (about 3,836 miles per hour). The weaving aspect involves producing materials that, among other features, are heat-resistant at that speed.

According to the company, it has 5,600 employees spread among 30 facilities in 13 countries. Its new worldwide headquarters in Portsmouth consolidates some of those jobs into the new facility. Its Albany, N.Y., office, for instance, will close. According to the company, the 30 corporate employees there have been invited to the Portsmouth office. If they choose to leave, the company says it will provide career support and severance.

Kleveland is a former fighter pilot with the Royal Norwegian Air Force, who before coming to Albany International was president/CEO of Textron Specialized Vehicles, makers of a wide range of recreational vehicles, including golf carts, all-terrain vehicles, and snowmobiles.

He name dropped former Gov. Chris Sununu, who, according to Kleveland, came to a board meeting and made a case for why the company should stay in New Hampshire. He also singled out Michael Bergeron, a business development manager with the state Department of Business and Economic Affairs. Kleveland quoted Bergeron as telling his board: “Stay here, consolidate your headquarters in New Hampshire. New Hampshire is a great place to do business.”

In a social media post, Bergeron said, “Albany considered other states along the east coast but chose New Hampshire based on skilled talent, quality office space, low taxes, business friendly attitude, and the New Hampshire seacoast was just a cool place to live and work.”

Gov. Kelly Ayotte, in her remarks, noted her family’s ties to aerospace — her husband, Joe Daly, is a former A-10 pilot who flew combat missions in Iraq, and her daughter Kate is a cadet at the U.S. Air Force Academy.

“I will say that one thing I love about what Albany does is it very much relates to a passion that Gunnar has and then my family has as well when it comes to aerospace,” Ayotte said.

“So we like to talk about what happens in those important moments for our military and especially in our aerospace and the important work that’s done here on that front, not just on the on the paper front, which is important, but also for what we see in the air and not only for our military, but for our commercial use,” she added.

She said she looked forward to working with Albany International on such issues as workforce development and housing. “Count me in. I look forward to that partnership,” she said.

Albany Safran has had an academic/vocational relationship with the public education system over the years. The Great Bay Community College’s Advanced Technology and Academic Center (ATAC) in Rochester was created in May 2012 to train students in the advanced weaving techniques used by Albany International for eventual hiring in the Albany Safran plant.

That program is no longer active, but the company is looking to partner with the University of New Hampshire, whose Durham campus is situated between the new corporate headquarters and its Rochester facilities.

UNH president Elizabeth Chilton, who attended the ribbon-cutting event, noted the current use of interns by the company and the hope for future opportunities.

“We’ve already begun conversations with Albany around areas where our strengths align, whether it’s in research or workforce development or innovation, and we really look forward to continuing those discussions,” she said.

“This new facility represents a commitment to this community in creating opportunities and advancing ideas that really make a difference,” Chilton added. “UNH is excited to be a partner in this journey and all of your future success. So congratulations on this remarkable achievement and thank you for the example that you set for our state’s future.”

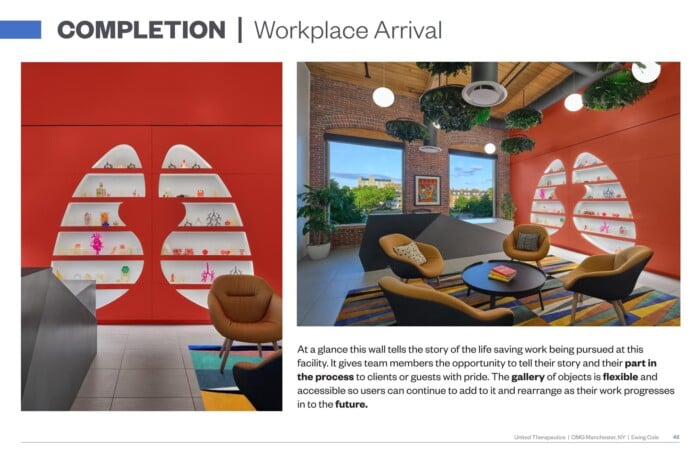

Albany International leases a part of the first floor and all of the fourth floor of the four-story, 100,000-square-foot building at Pease. The company says it will ultimately have about 100 corporate employees working there when it is fully staffed.

A tour of the building offered guests a look at the collaborative workspace as well as other amenities such as an on-site gym.