‘The company was founded here in Contoocook, and we’re very proud to be here,’ says Prototek CEO Bill Bonadio. ‘We want to continue to be part of that community, so we see really big opportunities for us to continue to grow.’

Founded in 1987 in Contoocook, Prototek is a digital manufacturing service bureau offering low-volume production and prototyping with services such as 3D printing, machining, sheet metal welding and assembly, and much more.

Bill Bonadio initially joined the company as CEO in 2023, bringing with him a breadth of machining knowledge from such firms as the Boeing Company and Danaher. Prototek marks the second small manufacturing company he’s joined as CEO, where he’s working diligently to develop a nationwide brand into one cohesive culture.

Q. Prototek has locations around the country, but its roots are local to New Hampshire, correct?

A. Here in Contoocook, this is our corporate headquarters and our original site. So, it keeps it close to home a little bit for everybody. Much of the workforce is from around this local area. We have incredible skilled craftspeople here creating parts for our customers. You’d be amazed at things that we do for parts, for appliances to bicycles and consumer goods. And we’re also doing work with semiconductors.

Q. Is the supply chain still a challenge?

A. It’s less of a challenge for us because of where we sit in the supply chain. We’re typically taking raw materials such as sheet metals and plastic resins, and we are then creating the parts that go into the assemblies and final products for our customers. So, it’s less of an issue than it was two or three years ago.

There’s a synergy and a benefit from sourcing locally. And there is a local supply chain and industrial base here. Although we have sites at different places around the country, we tend to try to source locally, because it’s usually better pricing and the cost of shipping as well.

Q. How are you working to overcome workforce challenges?

A. What we’re really talking about is a national problem, and it’s a shortage of people that have the skills and the fortitude to want to do these kinds of jobs and the kind of work. Here in New Hampshire, we know that the unemployment rate is exceptionally low. So, there’s not a lot of people looking for work. And to have people move here, there’s also housing. You need a lot more housing than we have. What we find is we’ve got to train our own people, and we consider workforce planning. So, when we have people come in here, we want to do what we can to retain them, to inspire them to be here, but also to give them opportunities to learn new skills and train them. Whether it’s sending them to schools or really getting more of a mentorship program going here in place and learn as you go. And that’s not always easy. That’s changing some of the culture — the way things used to be done as well, where you have your more experienced employees who want to focus on what they want to do, and it takes time to train new people to do things. But in the long run, that’s beneficial for everyone to have a more trained workforce that can handle multiple types of jobs and help you keep growing.

Q. Prototek recently announced new mergers. Can you share more about that?

A. Prototek acquired several companies in different places around the country. We have facilities in California, Wisconsin, Colorado, Pennsylvania, and they bring great benefits to us. We’ve added new capabilities such as 3D printing. We’ve added not only machine capability but also expanded our customer reach. Most importantly, we’ve added great people to the company. And that’s where we’re focused on right now: How do we go from five or six different branded companies to one company — five or six different ways of doing business and cultures to one company? It’s become a big change initiative for us to harness these opportunities that are now presented to us.

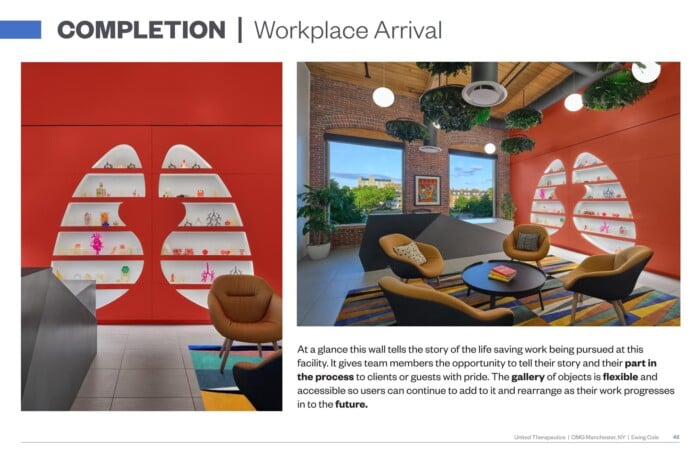

One of the things that I encourage the team to do when I got here was, we created a culture club, and we took people from different sites and in different roles in the company; it wasn’t just leadership thinking around big thoughts. I asked them, what should the company’s values be? Because if you would go to each one of our sites, several of them had their own value statements and what their beliefs were, they had their own mission and vision and they were all similar, but not quite the same. So I asked them to come together and make a proposal to us. And that’s some of the results that you see now on the walls here today. It’s trying to get people involved with setting the vision and the mission for the company.

And that’s very important to also have everybody be on the same page, too. We’re all working towards the same goals. Let’s do it together as a team.

Change is not easy. One of the challenges with change is the local culture versus the new national culture. It’s kind of like human nature. If you don’t change, you’re not progressing.

Q. What are your managerial values, and how do you envision continuing to lead this the team?

A. From a value standpoint, you want to treat people fairly right, and you want to be transparent, honest and fair. Those are important to me. I also want to be part of a team that wants to win. And in the business world, there are people wanting to take your customers all the time. They say they can do it better, create better value for your customers. So, we have to stay competitive; we need that spirit of continuous improvement and wanting to serve our customers, because the basics of business aren’t changing. Maybe the technologies are changing and the way you compete is changing, but I think those values of being willing to be innovative, being agile in how we do things, you certainly want to be delivering results with quality. And I think there’s a certain amount of resilience that people need to have, or perseverance, to see the job through.

Q. A lot of your branding includes the tagline “Innovation to scale.” What’s the meaning behind that?

A. The original Prototek was focused on prototyping, and the customers we served would be the engineers, the product developers, the entrepreneurs, and they would say, “I’ve got this idea. Can you help create it for me? And can you do it really fast? And do you know different iterations of it until we get to a final good?” But what has happened over time is that the customers of prototyping now are like, “Now that you’ve made it, can you make more of these for us? Can you help us with initial production? Can you eventually get us to scale?” They wanted certain quality levels and standards. So, we had to evolve our vision from being just rapid prototyping to actually making sure our customers knew that we have the capabilities to do both prototyping and scale production for them.

Q. How has digital manufacturing evolved over the past few years?

A. Digital manufacturing is very exciting. We’re seeing automation being brought to the factories. So, you’ll see things like smart factories being created. How can we do things without paper? I think the supply chains are now changing as we go to more of a digital technology-based world. There’s more connectivity between the supply chain trying to drive efficiencies. We’re seeing it in that customer experience, and customers are demanding more seamless, easy-to-purchase experiences from us. How can we have better connectivity? And then they want their answers faster.

As technologies evolve, people are used to going to Amazon and searching for a sheet metal part and getting a price. Now technologies are starting to come online that can do that. We need to be part of that evolution. And it’s also driving business model changes. As you become more connected online, it’s creating more availability and transparency in the marketplace. If you can couple that with smart technologies, we have companies that have made their business models market-makers. They don’t make anything, but they can go to customers and say, “We can find your suppliers faster for you than you can and get you better prices.” And then they’ll go to companies like us and say, “We’ve got customers now that we can bring to you and bring you this business that you can bid on.” So, that’s changing the dynamic, which makes us have to get more digital and do our work more efficiently and connect with our customers.

The rules of the game are changing and how we do our business, the fundamentals. You still have to serve your customer. Create value for them. Deliver their product or service on time. The way they want it at the right quality. Those don’t change, but how they want to procure that, how they want to be served is changing. And so, if we don’t find ways to stay ahead of the technology curve, we’ll continue to fall behind. We’ll lose share and could become irrelevant.

Our vision is always looking ahead to where we need to be, and be more digital. Our reality today is always a step behind in terms of the investments we need to make and the changes we need to make to be more effective.

Q. Do you have any projects or initiatives coming up that you’re really excited about?

A. There’s a lot of things going on right now, but we have to be mindful though, too, right? We have to run the business, and we have the people in place to run the business. And at the same time, we’re asking them to evolve and change and invest in the future. And those things can often lead to questions of how do we accomplish both of those things at the same time?

I’d say our first step right now is to be a good integrated company. We’re moving towards building better customer relationship management. If only customers could realize the other things we could do, we could be a bigger supplier for them and that could be a source of growth for us as well.

We’re also starting to look at things like artificial intelligence. It’s how can we take the knowledge that we have and leverage it with automation and/or artificial intelligence? We have this inside knowledge of how we receive customer requests and requirements, and then convert them into finished goods for them. That’s a great opportunity to take that type of data set, because artificial intelligence is only as smart as the data. So it’s, ‘how can we do this better? Can we do it faster? How can we support our team to do these type of things?’ You can use these technologies now for scheduling, forecasting, developing contracts.