Tony Fernandez, president and center director for the NH Manufacturing Extension Partnership

In late October, the NH Manufacturing Extension Partnership (NH MEP) hosted the 21st annual Governor’s Advanced Manufacturing and High Technology Summit in Concord, bringing together legislators and manufacturing leaders to network with one another and learn more about challenges and successes in the field.

Sponsored by M&T Bank and a plethora of other similarly focused companies — such as Eversource, BAE Systems, Mainstay Technologies and the U.S. Small Business Administration — the summit included a keynote from Jesse Stoneman, deputy director of public engagement for the CHIPs for America team, as well as addresses from Senator Maggie Hassan and representative Chris Pappas. Other topics discussed included the impact of AI on manufacturing and a women in manufacturing panel.

Leading the charge was NH MEP President and center director Tony Fernandez, new to his role, whose goal was to bring manufacturers together so they could collaborate and educate each other to develop a strong manufacturing ecosystem in the Granite State.

Q. You’re relatively new to the role at NHMEP. What’s it been like for you so far?

A. I’m new to the NH Manufacturing Extension Partnership, but I’ve been a client for over 20 years, so knowing how it works and the benefits of it are something that I’ve experienced firsthand. I actually started as a client around 2000 or so in the state of Wisconsin. I was fortunate enough to get my first president’s job, and at that time we needed to change over our business plan. We went from a distribution-based model to an OEM model, and as a result of that, one of the first people that we had that came in was the Manufacturing Extension Partnership in the state of Wisconsin.

Every center or every state has a different business model, but basically theirs was more of a collaborative where the bigger companies — the John Deere’s, the Harley Davidsons — basically work with the MEP to train and educate smaller companies, to work with them to get a better value stream and a better supply chain, because in that case, what was happening is mostly through the Midwest.

Q. The partnership offers workshops, training and resources and services that are essential to these small to medium-sized manufacturers to help them succeed. Can you share more about that model?

A. In New Hampshire, we’re a part of the U.S. Commerce Department. There are 51 areas, all 50 states and Puerto Rico, which has an MEP. The bigger states like Ohio or New Jersey or New York or California, states that are heavily invested in manufacturing have multiple centers.

The way we work is we get 100% funding from the Commerce Department, and most of the states get some sort of a state matching. Unfortunately, here in the state of New Hampshire, we do not get that matching. What we are is dependent upon workshops and different collaborative events that we have that we can raise some funds, so we can educate and help the manufacturers of New Hampshire.

What we’re trying to do is go and search out the manufacturer who needs some sort of help. And it’s a lot different today comparative to what it was years ago. What manufacturers, primarily here in New Hampshire, are looking for is sustainability. And when I say sustainability, we have a lot of small shops that are looking for some sort of a growth plan.

We have problems, obviously, with workforce, but they also need to develop their workforce. They need to understand leadership qualities. They need to understand the value chain. They need to understand the supply chain.

What we’ll do is we’ll go in, we’ll do an assessment for these companies, and from that we’ll work out a program that will help them gain some sort of sustainability. And again, the key thing for now is to look at it from a management standpoint as opposed to an engineering standpoint, which the MEP did for so many years.

Q. So would you say that companies get the most benefit if they’re at a point where they want to grow?

A. (Companies) were at a place where maybe they need to add more capacity in some way.

The situation that you have right now is workforce is so dominant in the question of growth. I’ve been to companies where they have maybe 10 or 12 employees. They’re doing well in some cases, maybe exceptional. Well, in order to go to that next step, they’re going to have to hire. And that’s a real, real problem here with unemployment being less than 2%, with the inability of bringing in skilled workers from other areas because of housing.

There’s a lot of restrictions and a lot of components that we have here in the state that we’re going to have to figure out before. What we’re trying to do is to work within the infrastructure that they have. Obviously, from a lean aspect, you want to get better quality, you want to get better efficiencies and things like that. But the key thing that what we’re finding is most manufacturers today are looking for workforce development. Now that we have these people, how do we keep them? How do we develop them? How do we make them better? How do we get them more productive?

Q. Are apprenticeship programs, those types of partnerships, something you’re working on to find pathways for these companies?

A. The process that we’re looking at right now is more of a collaborative atmosphere. The amount of manufacturers that we have here in the state is about 2,000 or so. But of those 2,000 manufacturers, probably 1,000 or more are small with 10 or less employees.

When we’re looking at these companies, we have to look at them as sole entities. How are these companies going to be able to weather and sustain in the near future?

One of the big things that we have out there is technology and, in order for these companies to grow in in any manufacturing company, you have to have the ability to innovate. A lot of what we’re doing with these small companies is working with them within the workforce, but also training them with the latest manufacturing processes and hopefully igniting some people within the organization to develop an innovative plan. That’s the key thing. If you’re not going to innovate, especially in a small manufacturing company, it’s going to be a disaster.

Q. Can you share more about the Summit in October?

A. It went exceptionally well. We, as a group, were happy because the one thing that we wanted to do in this event, more so than in the prior years, was developing a networking atmosphere within the manufacturing community.

Having worked in different areas of the country, one of the things that you see is that the New England mentality is a much more parochial mentality. Everything is confined, but in New Hampshire it’s even more confined. It’s even more sequestered. And it’s a real problem from an innovative standpoint.

From the chips and supplies sustainment aspect, what you have is a lot of small manufacturers who are doing great work, who have never had the ability to communicate with each other.

That communication is important for two reasons. One, it’s important from understanding what you’re manufacturing, what your capabilities are, but it’s understanding from the supply chain that there might be somebody who might be able to give you a product.

And I have found in the past four months or so that there are companies here in manufacturing in New Hampshire who are buying from China, who could basically go from 3 or 4 miles down the road and get that same product. But there’s never been a real collaborative or cooperative assessment out there to try to get these people to talk to each other.

So, what the summit did is it gave the availability of manufacturers to come in, and we got a lot of positive feedback.

The summit itself was made up of three different components. We had the CHIPS Act and Jesse Stillman from the Commerce Department did a great presentation. She was able to explain the CHIPS Act and as a simplistic form as possible.

We had Kyle Schofield from the State of Maine State. He was probably the star of the event. Scared a couple of people, but at the same time, he was very informative with both the benefits and the cautions that you had to have out there. And the third part of the process itself is we had the women in manufacturing panel, which was headed by Amy Bassett.

That was really important to me, because one of the things that we have to understand, especially in manufacturing comparative to business is the amount of women who are taking leadership positions.

I know in the conversation itself, some numbers were quoted, but mine is the eye test going into factories here, going into businesses, I see more and more women in leadership. I see more women on the factory floor. So from that component, it was really important that we got that narrative started.

And the last thing I’d like to talk about is the two people from the both the federal government and from state representation, Maggie Hassan and Chris Pappas. I was really happy that they showed up, because it showed a commitment to manufacturing. And that’s really what we need.

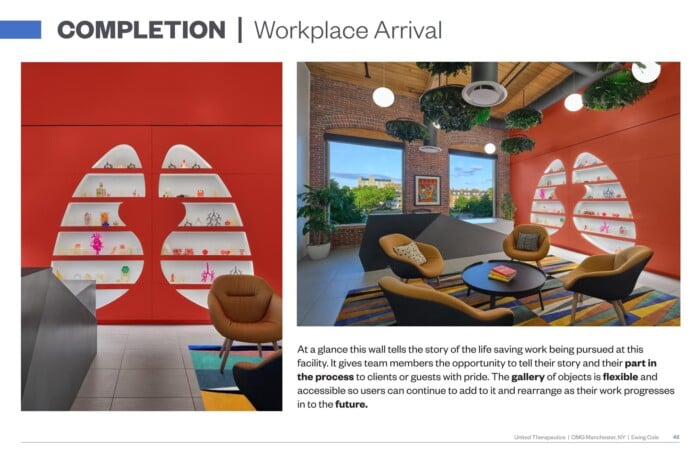

Q. The Manchester Millyard was recently named one of 31 tech hubs in the country that will be able to compete for federal funds. We’re talking about developing human tissue, bones, organs. The building next door to us is working on artificial lungs. Tell us about the impact of that.

A. Well, it’s important to understand that what the word manufacturing means, and it’s changed dramatically over the past five, 10 years, when I graduated from college, manufacturing was that dirty place that you went. And it started to change. You got more into the high tech, pharmaceutical areas. You got into the aerospace. And it started to change over that period of time.

And with ARMI (the Advanced Regenerative Manufacturing Institute), it’s a different type of manufacturing. It’s the manufacturing of something that’s very important to a lot of people. It’s components, it’s tissues, it’s things like that that are going to save lives. It’s things that are going to give us the availability to live a much more productive life.

So, when you look at manufacturing, you look at it through many different prisms. The one key component of manufacturing is that it should always make it easier and it should make it safer. And in this case, with the evolution of what is happening with ARMI, it’s going to make it to the point where it’s going to allow you to live a healthier and a longer life. It’s amazing the different processes and the different components we actually have. Hopefully in the next couple of months or so, we’ll get more involved with that.

Q. What are your plans for the partnership in the near future?

A. One of the things that I have or in my quiver is that I’ve been a client of the MEP, so I know the benefits of the MEP client in two different areas of the nation in Wisconsin, in Massachusetts.

The good thing that I’ve always seen from a client standpoint is the helping. They have the availability to give you instruction, give you support and give you education. The situation that we have in the state of New Hampshire is a funding issue. And as a result of that, what we’re trying to do is develop a secondary source. And I don’t mean state funding or things like that. We’re going to develop a source that hopefully we can work with that will give us the availability to touch more people. And when I say touch more people, those are the small people. It’s very difficult for a seven-person operation to spend $30,000 on a project or a commitment. That’s a half a salary.

In order for them to grow and be sustainable, we’re going to have to figure out a way of helping these people.

In the state of Wisconsin, for example, the bigger companies do that. They will go in and they will either put through a grant program or some sort of a feasibility study that will allow dollars to be paid through the MEP or whatever other process that will allow that to happen. And the state of Massachusetts, there are a lot of grant programs. Unfortunately, as I’ve said in New Hampshire, we’re going to have to be a lot more creative.

One of the things that I’d like to do is to adopt a philosophy of the model that they used in the state of Ohio. The way that they support manufacturing in Ohio is through a lot of grant programs. Hospitals, banks, cable companies, organizations like that, by law, have to give back some of this to the community. And one of the things that the Ohio model has been able to do is to educate these organizations. What we do here at the MEP is educating, we are informing, we are teaching. And as a result of that, we become very fertile.

Cleveland Hospital gives a ton of money to the Ohio MEP. Why is the hospital doing that? Well, it’s because it’s the right thing to do. Because you have moms, single mothers who need health care. They can use those dollars. If you don’t have health care, child care, you’re not going to have manufacturing in today’s world. That’s the vision that we have down the road.

One of the things that came about as a result of the Summit is, over the weekend, the amount of emails of people who now want me to talk, which is good. I would be more than happy to explain what the MEP process is and how we can help manufacturers.

For 2 or 3 years, I was kind of semi-retired. I had been a CEO of a company. The pandemic came about and kind of washed my dreams away. So, for the past couple of years, I had a consulting business. I was teaching in an MBA program at a college in Massachusetts, and I was the Western Massachusetts director for SCORE. I kept myself in the game. But really, what I want to do, is educating. There’s something you got to give back because, if it wasn’t for the MEP, I wouldn’t be where I am today.

One of the more important things that we have to do is we have to get manufacturers and legislators talking, because in the CHIPS Act, what you have is the availability of a lot of money, but you also have a lot of misinformation out there, and it’s going to take a collaborative event. And that was one of the things that Deputy Stoneman had talked about in order for this CHIPS program to work, particularly here in the state of New Hampshire, there’s going to be a lot of collaboration.

And the way the federal government wants to put it out, it’s not going to be like the money where they give money to states and cities and to businesses. With these $200 million grants, you could build hundreds of factories or 50 factories. In order to do that, you’re going to have to get five, six different companies together. You’re going to have to get the social service agencies. You’re going to have people who are going to build housing. Day care is part of the process.

There are so many different components in order for this to work. The Biden administration said that the MEP was going to administer it. The proof is in the pudding. We’re getting much more involved in it. But the reality is we’re going to need some more help.

Wages are going up as a result of many different factors. But the bottom line here is that in order for us to have sustainability, we’re going to have to start manufacturing again in the United States. And obviously, it’s going to mean that products are going to be much more expensive because we’re not going to have the third-world pricing structure.

(Consumers) want two things right now. They want quality, and they want availability. What we’re finding right now is you need availability and quality. If you could put the quality into the product and if it’s available, they’ll figure out a way to get it basically paid for.

One of the good things that we’re going to get out of this is that when you look at the job picture out there, manufacturing is one of the few industries that is still going to be hiring over the years, and it’s going to be hiring at a higher pace.

It’s a great time to be in manufacturing. I’ve been in manufacturing for well over 45 years. The manufacturing sector took a real big hit in the ‘80s. Everybody offshored. And it was the thought process that was the thing to do. There were other jobs out there. There were the sexier jobs to be in, like technology, customer service. But we’re going to have to bring it back into the United States. As a result of that, there’s going to be a lot of opportunity. And one of the things that we’re going to have to look at is the different types of manufacturing, additive manufacturing, manufacturing 4.0, robotics.